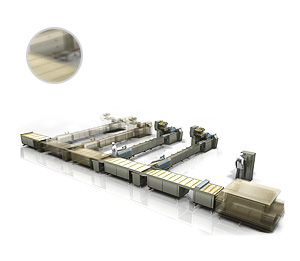

This product is the most optimized environmental protection composite packaging equipment that has been introduced by our factory with advanced technology at home and abroad. The whole machine adopts a segmented combination, which can be packaged and transported separately. It integrates machine, electricity and gas.Controlled by PLC program, respectively, heating preheating, bubble forming, automatic feeding, heat sealing, aluminum plastic belt synchronous adjustment, photoelectric detection lack of grain, hard aluminum forming, cursor-to-plate, two thermal side reactions, tangential pressure Mark, batch No., servo electromechanical traction, blanking, automatic waste rejection, waste recycling equipment, etc. This product is suitable for the production of aluminum-plastic, aluminum-aluminum, aluminum-plastic aluminum blister packaging, a multi-purpose functional equipment.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.