|

Refer to other manufacturers equipment

|

huayuan

|

sanhuan

|

lihong

|

Other manufacturers

|

|

Comparison performance list

|

SB800W

|

DYF-300A

|

PW0200

|

SMJ-SB-TG

|

|

Sealed output and packaging effect

|

Sealing effect

|

Reciprocating heat sealing effect is good

|

Roller seal effect is general

|

Roller seal effect is general

|

Roller seal is poor

|

|

Use packaging materials

|

100-140 packs per minute, stable

|

Maximum speed 50/min

|

Maximum speed 50 packs / minute

|

Maximum speed 60 packs / minute

|

|

Speed production

|

Two columns, one out of 2 bags, one out of 3 bags can be customized

|

Only one bag per row (low efficiency)

|

One out of one bag (inefficient)

|

One bag and two bags in a single row (inefficient)

|

|

Package output method

|

Both sides can be single side

|

Both sides can be single side

|

Both sides can be single side

|

Both sides can be single side

|

|

Cursor version

|

Net text compression and flattening

|

Roller press fit is easy to fold

|

Roller heat seal packaging seal is easy to fold

|

Roller heat seal packaging seal is easy to fold

|

|

intelligent control

|

error alarm

|

With fault alarm

|

With fault alarm

|

With fault alarm

|

With fault alarm

|

|

touch screen

|

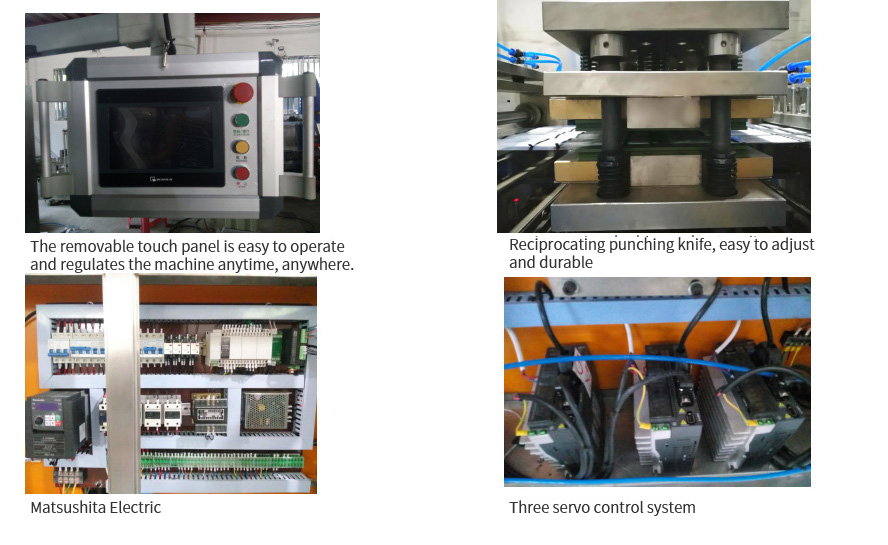

Movable touch screen, control the machine anytime, anywhere without the need for multi-person assistance

|

Fixed cannot move touch screen control

|

Fixed cannot move touch screen control

|

Fixed cannot move touch screen control

|

|

control method

|

Three servo

|

Double servo

|

Double servo

|

Old progress control

|

|

Automatic cutting

|

Can be customized according to requirements

|

Customizable

|

Customizable

|

Customizable

|

|

Punch coder

|

Easy to reciprocate punching and coding

|

Punch coder installation is cumbersome

|

Punch coder installation is cumbersome

|

Punch coder installation is cumbersome

|

|

Equipment material and accessories supply appearance

|

Equipment material

|

All use 304 stainless steel

|

304 stainless steel

|

304 stainless steel

|

201 stainless steel

|

|

Accessory rate

|

80%

|

50%

|

50%

|

30%

|

|

After-sales parts supply timely

|

Self-owned WeChat Taobao accessories store can be purchased, timely and convenient, no extension

|

The general review process is cumbersome

|

The general review process is cumbersome

|

The review process is cumbersome and requires a long wait

|

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units. Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.

Our company was established in 1996, with a total area of 20,000 square meters, with a total staff of 180 people and an annual output of more than 4,000 units.